Creating a Stock item in Advance Mode

Advance mode means enabling advance configuration and Features for stock item master in F12:Configure and F11:Features.

Shown below are the advance configuration parameters for stock item master under F12:Configure (Master Configuration) :

Shown below are the advance configuration parameters for stock item master under F12:Configure (Master Configuration) :

Shown below are the advance Features for stock items in F11:Features:

Note: You can configure the entire setup according to your requirements. According to the configuration in F12 and F11, stock item master fields will get added and removed.

Go to Gateway of Tally ; Inventory Info ; Stock Items; Create (under Single Stock Item)

A brief description of each additional field in Stock Item Creation screen is given below.

Part No.

This Part number field gets enabled only after enabling Use Part Number for stock items in Inventory Master Configuration. This field is used to enter the Vendors catalogue number. You can also optionally print it in reports/invoices.

Description

The Description field gets enabled only after enabling Use Description for Stock Items in Inventory Master Configuration. This field is used to enter the description of the Stock Item as it is required to be printed in Quotations, Delivery Challan/Invoice.

Remarks

This Remarks field gets enabled only after enabling Use Remarks for Stock Items in Inventory Master configuration. This field is used to enter Remarks for the Stock Item (for internal use only). Any additional details about the Item can be entered here.

Set/Modify Default Ledgers for Invoicing?

This option gets enabled only after enabling Specify Default Ledger Allocation for Invoicing in Inventory Master Configuration. Once you enable this option, a screen will be displayed for selecting the default ledger allocation for sales and purchase for the stock item.

Note: This option is useful only in case of Invoice entry through Voucher Class.

Category

This Category field gets enabled only after enabling Maintain Stock Categories in Inventory Master Features. This field will show the List of Categories. Here you can select the Stock Category under which the stock Item belongs. By default, Not Applicable is displayed in this field.

Note: You can create a new stock category by pressing ALT+C at this field.

Alternate Units

This Alternate Units field gets enabled only after enabling Use Alternate Units for Stock Item in Inventory Master Configuration. Alternate Units is another unit, apart from the main unit, which you can use for the Stock Item. This is particularly useful when you need to handle different units at different times.

Example:

1 Box contains 10 numbers of mouse. In some case, 1 Box contains 12 number of mouse. In this case, Alternate units is very useful. During entry, you can change the conversion factor between Box and number.

Maintain in Batches?

This option gets enabled only after enabling Maintain Batch wise Details in Inventory Master Features. If you want to maintain the batch information of Stock Items, set the option Maintain in Batches to Yes.

Track Date of Mfg?

This option is enabled only when Maintain in Batches? is set to Yes. If you want to specify the manufacturing date for the item, set Track Date of Mfg. to Yes.

Use Expiry Dates

This option gets enabled only after enabling Set Expiry Dates for Batches under Maintain Batch Wise Details option in Inventory Features. If you want to specify the expiry date of the item, set Use expiry dates to Yes. This option is useful for stock items like medicines, Food items, etc.

Set Component BOM

This option gets enabled only after enabling Allow Component List Details (Bills of Material) in Inventory Master Configuration. Refer to Bills of Material for more details.

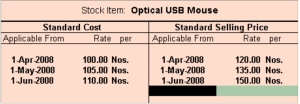

Set Standard Rates

This option gets enabled only after enabling Allow Std. Rates for Stock Items in Inventory Master Configuration. This option helps you specify standard purchase rate and standard sales rates for the item.

The standards are effective from the specified dates and they continue to be used at these rates until the next date, where the standard rate changes.

Note: Standard Rates can also be used for valu ation of closing stock.

The standards are effective from the specified dates and they continue to be used at these rates until the next date, where the standard rate changes.

Note: Standard Rates can also be used for valu ation of closing stock.

Behaviour Group

Once you enable Allow Advanced Entries in Masters Behaviour Group option will be enabled.

Options available under Behaviour Group are:

Options available under Behaviour Group are:

Costing Method

This field will display the List of Costing Method for valuating the Stock Item.

Depending upon the stock item, you can select the costing method for valuating the Stock item.

A Brief description about each Costing Method:

A Brief description about each Costing Method:

At Zero Cost:

Cost of an item is considered as zero. For example, for defective items that have no commercial value.

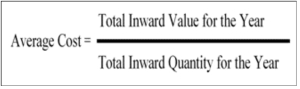

Avg.Cost:

Periodic system:

This is also known as Weighted Average Cost. The weighted average cost for the whole year is computed as below:

Monthly system:

In monthly average cost, weighted average cost is determined on a monthly basis instead of annual.

FIFO (First-in, First-Out):

Periodic System

Under FIFO Periodic System, it is assumed that items purchased first are sold first under the current financial year (i.e., first lot from the opening stock of current year).

Perpetual System

Under FIFO Perpetual system, it is assumed that items purchased first are sold first across the financial year (i.e., first lot may be from previous year entry).

So cost of goods sold is based upon the cost of material received first in the period, while the cost of inventory is based upon the cost of material received last in the period.

Last Purchase cost

Last purchase cost is Last purchase rate. Cost of goods sold and Cost of inventory is based upon the Last purchase rate.

LIFO (Last-in, First-Out)

Periodic system

Under LIFO, it is assumed that items purchased last are sold first under the current financial year (i.e., first lot from the opening stock of current year)

Perpetual System

Under LIFO Perpetual system, it is assumed that items purchased last are sold first across the financial year (i.e., first lot may be from previous year entry).

So cost of goods sold is based upon the cost of materials received last in the period, while the cost of inventory is based upon the cost of material received first in the period.

Standard Cost

Standard Cost is Standard Rates specified in the Inventory master.

Cost of goods sold and Cost of inventory is based upon the Standard Rates.

Market Valuation Method

By using Market Valuation Method, you can determine the realisable worth of an Item.

Unrealised Profit of an Item = Closing value as per Costing Method – Closing value as per Market valuation method.

Select the appropriate method applicable for the Item from the Valuation Methods List.

At Zero Price

Realisable price of an item is considered as zero.

Example: For defective items that have no realisable value in the market.

Average Price

Weighted Average is computed as the sum of all invoice value / sum of all invoice quantity for the financial year.

Last Sale Price

Item is valued at Last Sale Price.

Standard Price

User specified rate applicable for the current date specified in Item master under Standard Rate is taken as the realizable rate.

Ignore Diff. due to Physical Counting?

In Tally.ERP 9, you can record the physical stock as counted, using a physical stock voucher. If you wish to ignore the difference and continue with the stock as per books, set this option to Yes.

Ignore Negative Balances?

If you set this to Yes, Tally.ERP 9 ignores the item in the stock reports, in case it has a negative balance.

Treat all Sales as New Manufacture?

If you set this to Yes, whenever a sales entry is made, Tally.ERP 9 automatically updates the quantity and value in inward by treating the same entry as a New manufacture or purchase.

Treat all Purchases as Consumed?

If you set this to Yes, then, whenever a purchase entry is made, Tally.ERP 9 automatically updates the quantity and value in outward by treating the same entry as consumed.

Treat all Rejections inward as Scrap?

If you set this to Yes, then, whenever a rejection inward entry has been made [without tracking number], Tally.ERP 9 automatically reduces the amount from the closing stock balance. In this case, you need not pass the credit note for reducing the value against rejection inward.

This is used for defective items returned by the customer.

Allow use of expired Batches?

This option will get enabled once you enable the Use expiry dates under Maintain in Batches option.

If you set this to Yes, during selection of batches in voucher entry, expiry batches also get included in the List of Active Batch.

No comments:

Post a Comment